Share

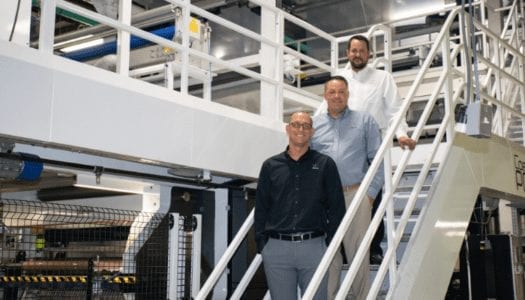

Versa Pak President Michael Brunswick, Sales Manager Jeff Knapke and Plant Manager Scott Knapke recently sat down and answered questions about how Versa Pak has been handling the COVID-19 pandemic and updates at our manufacturing plant.

Watch the video below to learn more.

Have lead times changed during the pandemic? What is a typical turnaround time?

Jeff: Lead times have changed. In the last probably two weeks we’ve seen somewhat of a slowdown. Last year we were pushing a three-to-four week lead time on average. Now they’re down to two to three on average with some lines under two right now.

Have you had to change any processes during the pandemic and going forward?

Michael: Based on the ever-changing guidelines from (Ohio) Gov. Mike DeWine, some of the things we’ve implemented are temperature checks when coming in every day, sanitizing stations that we have and we’re sanitizing our operating areas twice a day. Other than that, just typical protocols and adjusting our cleaning schedules so we’re focusing on high-traffic areas.

What kind of testing do you do? How do I know my packaging will perform as I need it to?

Michael: We can perform a lot of different tests; anywhere from a dart, tear, COA, elongation, Spencer impact, phase testing, tensile testing, VCI strength. We have many different tools that we can utilize.

During the process, we have a checksheet that goes through every hour. We check any specifications from width, mill, print depending on the application. We also have a two-hour quality check, a separate check, so throughout the process, it’s checked multiple times by different people.

I need a new packaging solution that we’ve never tried before. How can you help me?

Jeff: Versa Pak has a lot of different options that we can produce for you. One thing in mind is shrink; we’ve been getting a lot of calls on shrink applications right now. What we do with that, is we’ll send the pricing first. If the pricing is approved, then we’ll go into a roll testing, and if that is approved, then we’ll move onto the order.

If anyone needs something new, they know to call or email. We are still here in the office. Then, we’ll go into sample mode if need be. Or we can do a Zoom meeting if we need to see an application that is needed. They can put their camera on, and we can see it from our office into their plant.

What sort of information would someone need to provide to Versa Pak before you could produce the new project?

Jeff: Being a custom manufacturer, we’re going to need the width of the bag or the sheet, we’re going to need the mill, we’re going to need the footage or roll count of how many bags they want on a roll. We also like if they can let us know what the end application is, that helps us out designing the right material to use, etc.

Michael: We also need to know information with regards to if they have a certain slip level, dart, haze — kind of the testing we talked about before. If there is any specific information, it would be great to know that ahead of time and any sort of print specifications because we order print plates and it’s a longer process, so all that would be helpful.

What goes into a quote that you would provide me? How is pricing determined?

Jeff: We need all the information from the purchaser or salesperson. Being a custom manufacturer, we do by size, width, mill, etc., and of course your small bubbles versus larger bubbles.

On the large size, your price is going to be a little bit cheaper because it runs a lot faster versus a 5-inch tube or bag run a lot smaller. Then freight depending on where we’re shipping to. If it’s in Ohio versus, we ship a lot out of Utah. Freight is going to determine that price as well. And all the additives that go along with it, etc.

Fill out this form to start your custom quote >>

How are you staying connected with your distributors and customers during this time?

Jeff: Right now, we still send out our marketing newsletters through our marketing team to keep them updated on any changes that we have. We also are doing quite a few Zoom calls with our distributor base, our sales reps, trying to stay connected that way.

We have been reaching out to some of our customers, depending on what state they are in, to see how fast they are reopening, what their policy is – if you can come in and see us now. It’s kind of a work in progress, but we’re trying to stay connected and day-to-day is different with every state and how we’re trying to connect with our distributors.

Do you provide samples of a solution before it would be produced so I know what to expect with the final project?

Jeff: We do samples for our customers, and we try to get all the information upfront as much as possible. Being a custom house and being around for quite a few years, we do understand a lot of the different industries out there, so we can. Like Michael said before, with all of the testing we can do once we get the information from them.

Versa Pak has had a lot of expansion over the years, what do you have currently going on at your plant?

Scott: A few months back we got all three of our five-layer lines running and they’re currently running right now. We purchased a new sheeting line a few months back, and it’s probably going to be installed mid-summer. Our shrink bundling line was at capacity all of last year, so we made the decision to buy a brand-new line, upgrade liners and so forth. That should be coming this summer.

What would happen if I’m not satisfied with the finished product? Is there a guarantee in place?

Michael: With Scott as our plant manager, we have very few unsatisfied customers. If there is an issue that arises, we want to take care of it and get it back here and issue a corrective action so we don’t have the issue again. One way or another, we make sure the customer is satisfied.

Innovation, Reliability and Consistency: What You Can Expect When Working With Us

At Versa Pak, we’re constantly expanding our product lines to meet our distributors’ needs. Click below, to learn more about our capabilities. Or contact us to develop a custom product for your end result.