Share

Polyethylene (poly) bags and sheeting are used across multiple industries and have various end-uses. Used for protecting everything from car parts to packages in your mailbox, poly products are the material of choice for many applications.

Because of its versatility (polyethylene can be custom-manufactured to meet different strengths and capabilities depending on the end-use), poly bags and sheeting can be used for multiple purposes.

How will your customer use their poly bag or sheet product? In this resource, we’re breaking down a couple of the common polyethylene bags and sheeting end-uses by industry.

Automotive Industry End-Use Applications

One of the most common polyethylene products Versa Pak produces for the automotive industry is VCI rust inhibitor bags. VCI — which stands for Volatile Corrosion Inhibitor — is a material that protects products from rust and other types of damage.

The VCI additive is added to the makeup of the resin blend, and once it is sealed off, the product prevents the product from rusting. The bag can be used to wrap a metal car part to prevent rusting, such as during the shipping process.

At Versa Pak, we also have the ability to check a sample and final product for VCI testing requirements.

Medical Industry End-Use Applications

Another common end-use application for polyethylene bags is secondary medical packaging, which would be used on top of a cleanroom-certified bag.

An example of an end-use for this type of poly bag would be bags used for items such as breathing or incubation tubes.

Some other polyethylene product end-uses in the health care industry include shrink film to wrap hospital gowns and bedding, as well as soiled linen bags and protective barriers.

As part of Versa Pak’s measures, we routinely audit our process and products to ensure we meet medical specifications; however, we are not cleanroom certified.

Related: Read How Versa Pak Supported Health Care Workers on the Frontline During COVID-19

Food Industry Applications

When choosing a bag for food storage and shipping, you want to make sure that your customer’s product is puncture-, tear- and leak-resistant, as well as able to keep food fresh.

For this reason, poly bags and film are commonly used in the food industry, such as at food processing plants.

Here are a few examples of some of the end uses of poly packaged custom products we’ve manufactured at Versa Pak:

- Pizza crust wrap

- Pork chop bags

- Bulk packaging

- Gas-flush poultry bags and films

Because it’s important for the packaging our food comes in to be as safe as the food you eat, at Versa Pak, we hold multiple food safety certifications, such as SQF, Kosher, IMS and more. Learn more about our certifications here.

Manufacturing Industry Applications

When shipping your items, you want to ensure the item packaged is not crushed or ruined in transit. That’s where our industrial applications come in, such as pallet covers and construction films.

If you’re concerned about crushing or tears when it comes to poly bags and films, Versa Pak’s research team can test the product for strength, such as the DART machine and the Spencer Impact machine, shown in this video.

We also produce Gaylord box liners, which are polyethylene films that fit inside a box and are used to cover the bottom and sides of a container.

Miscellaneous Poly Film End-Use Applications

When you’ve driven down the road during election season, have you ever thought about what material those election signs are made of?

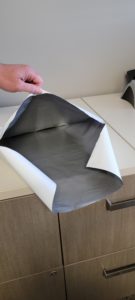

Perhaps not. But, in fact, those signs are made of black and white signage poly film.

By utilizing a master roll, Versa Pak can print the design on the white side of the film, with the inside being black, enabling the sign to be opaque. The film would then be cut down into signs at a print shop.

Another example of a common poly film application (which you may find in your own mailbox!) is mailer bags.

In most cases, Versa Pak manufactures the gray/white, silver/white or black/white film on large rolls and then uses a converter machine to convert the film into mailer bags, with the white side creating a printable surface.

Is Polyethylene Recyclable?

A question your consumer may also ask is if the poly packaging product is recyclable. And the answer is yes! Polyethylene material produced at Versa Pak is classified No. 4 plastic, or low-density polyethylene, which can be recycled.

At Versa Pak, our polyethylene scrap (among other items) is recycled through a sustainability program at our manufacturing facility. The poly scrap is transported off-site to a nearby company that is able to repelletize it for use in industrial items such as pallet covers, garbage bags, top sheets and more, all available at a lower cost for our consumers.

Learn More About Custom Poly Products at Versa Pak

All of our end products at Versa Pak are custom-made, which means we can work with you to meet specific requirements for the product’s end-use, make adjustments for sustainability and meet your budget.

To get a quote for a custom product, just click the link below. If you’d like more information about our quoting process — such as how long it takes to get a quote or our testing capabilities — click here to read about what goes into a quote for a custom poly bag or sheet.

Get a Quote